3D Photogrammetry for Projectile Deformation Analysis

Photogrammetry, Forensics, Ballistics, Projectiles, Project Analysis

All the data of this case study have been kindly provided by Rafael Rodrigues Cunha, Ph.D. in Analytical Chemistry from the Federal University of Uberlândia (Universidade Federal de Uberlândia) and Forensic expert of the Scientific-Technical Police of the State of São Paulo, Brazil.

The following article focuses on a photogrammetry technique tested to assess projectile deformation using 3DF Zephyr. We are incredibly proud to have supported this work with our software solution.

Rafael, along with Sarah Teixeira Costa, Rodrigo Henrique de Oliveira Montes, and Claude Thiago Arrabal, came up with a rather simple, fast, yet effective workflow which has been fully presented during InterForensics 2021, considered the most important Forensic Science event in Latin America that took place on November 2nd to 5th, 2021 in Foz do Iguaçu/pr, Brazil.

Project Goals

“The objective of this work is to develop a procedure using simple, fast, and low-cost photogrammetry technique to assess projectile compression in different targets, calibers, varying shooter distance to establish a relationship within the specific deformation changing.”

According to the research carried out by the team, it’s shown that, statistically, firearms represent one of the major causes of deaths worldwide; besides, in 2019, 70% of homicides registered in Brazil were caused by firearms. Starting from this piece of information, Rafael and his colleagues wanted to set up a photogrammetric approach that could evaluate deformations in projectiles by generating 3D models that could indicate the deformation of the referred object after impacting a target.

To do so, 4 different full metal jacket calibers – 9 mm LUGER, .380 AUTO, .38 SPL, and .40 S&W – were selected to perform shots, with 120 cartridges each, kindly donated from CBC (Companhia Brasileira de Cartuchos). The projectiles deformation reproducibility was ensured by firing 3 times against 5 distinct materials chosen as targets (kindly provided by Centro de Treinamento Tático – CTT CBC):

- Plywood with Clay brick wall behind

- Dense wood

- Steel plate

- Clay brick wall

- Concrete brick wall

These objects were shots at five different ranges – 5, 10, 20, 30, and 40 m – to guarantee a good amount of data for the subsequent shooter distance analysis. After hitting, each projectile was collected in small plastic bags based on target material and distance.

Outputs

A Samsung Note 20 mobile phone was used for the photo acquisition step: on average, they shot about 30 pictures for each kind of material and each distance range.

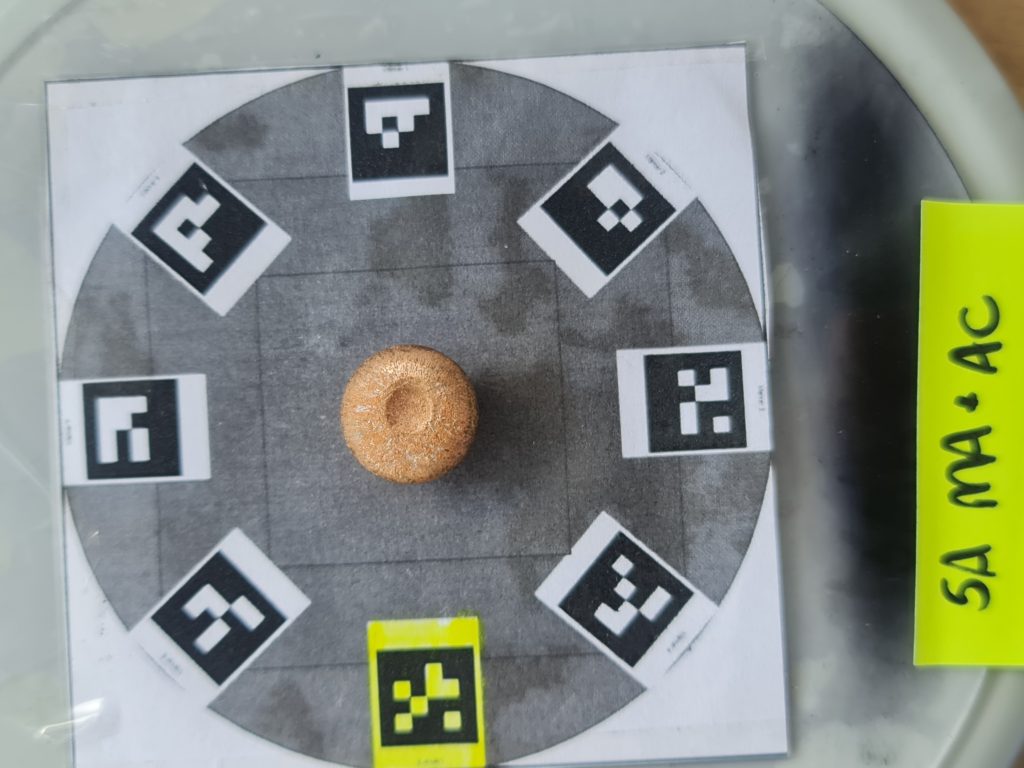

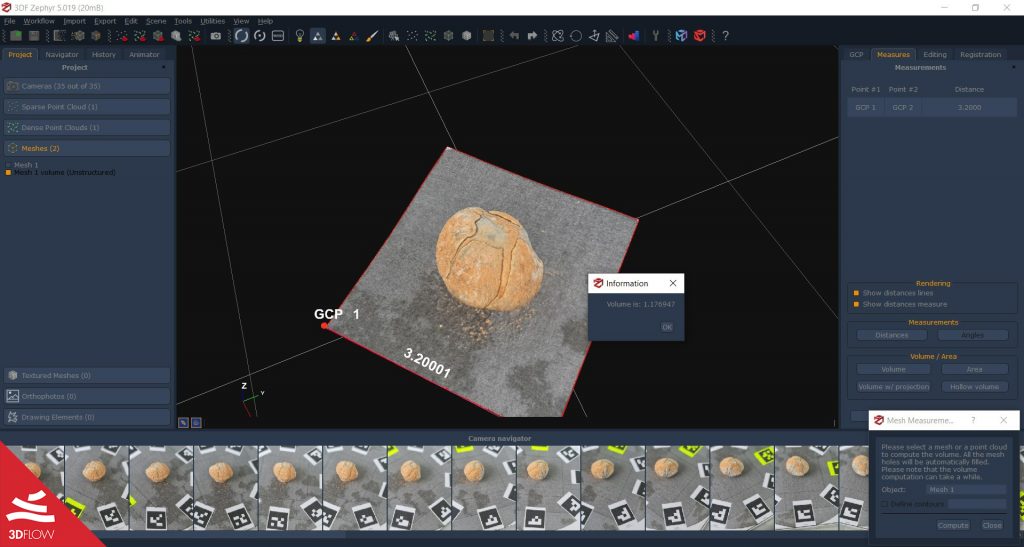

The usage of 8 coded 3DF Zephyr markers, placed all around a template with a 3.2 cm circular grid, significantly improved the 3D reconstruction process inside the software, with the bullets and the different targets placed in the middle of the grid upon an electric-powered turntable (Fig. 1-2).

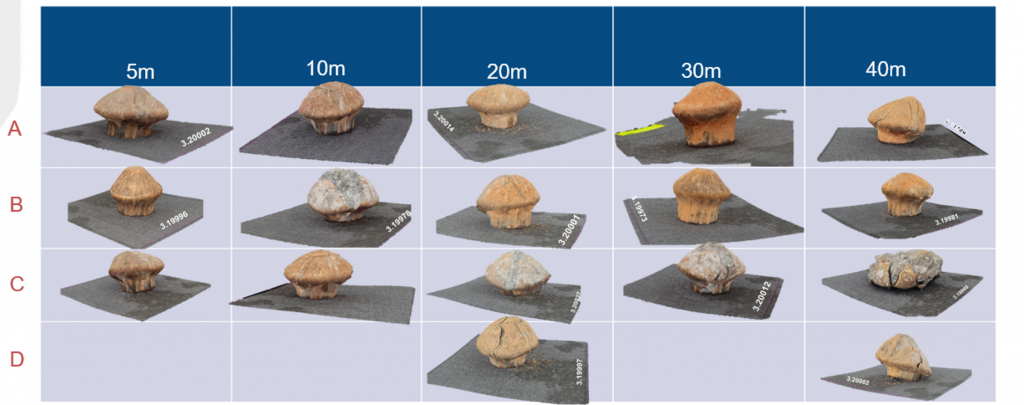

From all the 480 fired cartridges, only about 25% were recovered after clashing against the targets. In particular, the ones that had hit the steel plate suffered massive fragmentation and couldn’t get measured (Fig. 3). The cartridges recovered from the plywood target presented no significant deformation, indeed preserving the original shape plus barrel imprints.

Conclusions

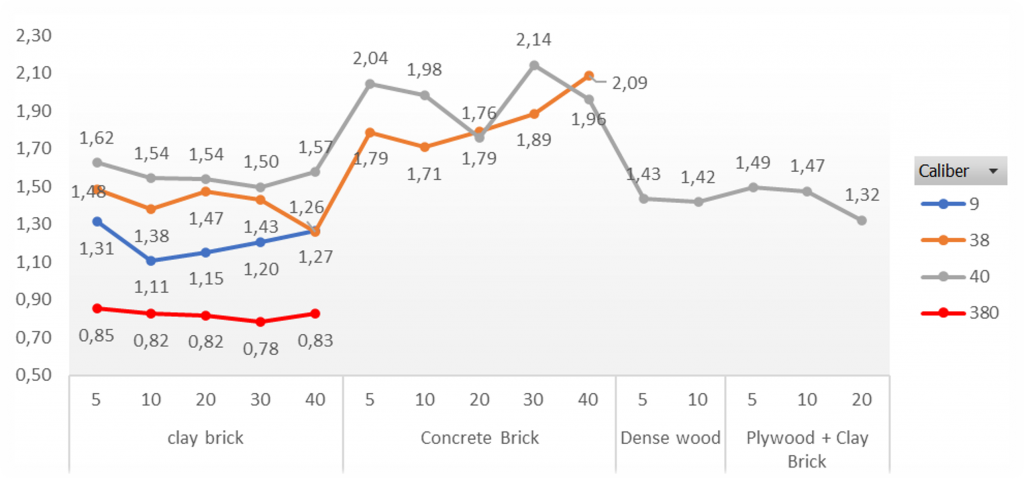

From this first round of tests and as displayed in the table below (Fig. 4), photogrammetry results matched expectations, especially concerning lower mass and energy with smaller deformations: the .380 AUTO deforms less than 9 mm Luger, showing potential to differentiate both, while .40 S&W and .38 SPL present similar deformation.

Although further analysis will be carried out on this matter, photogrammetry has already proven to be an efficient approach that can significantly help forensic applications and ballistic studies.

You can find the poster of the project displayed during InterForensics at this LINK.